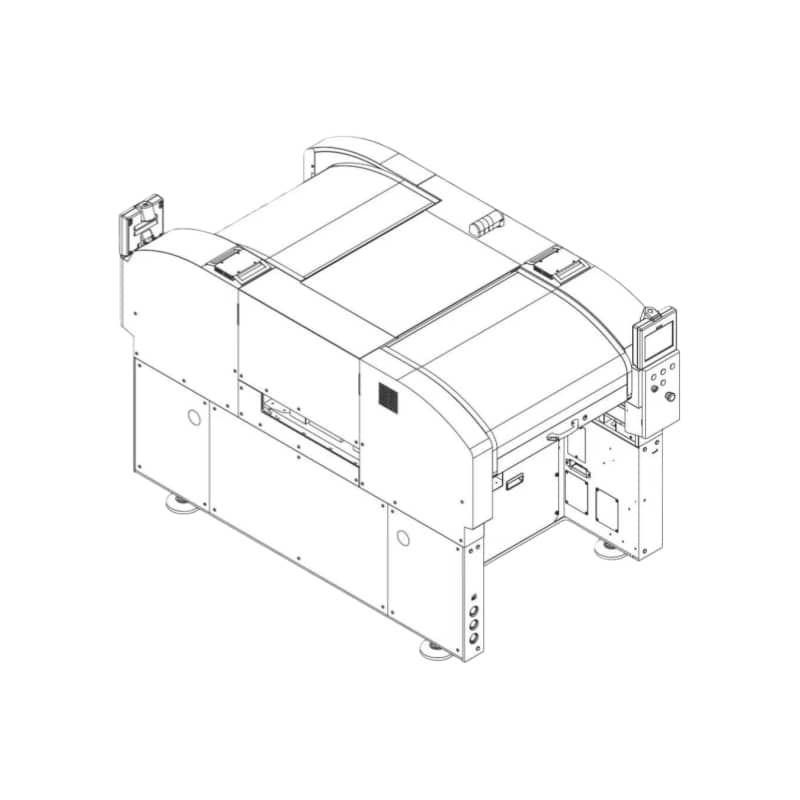

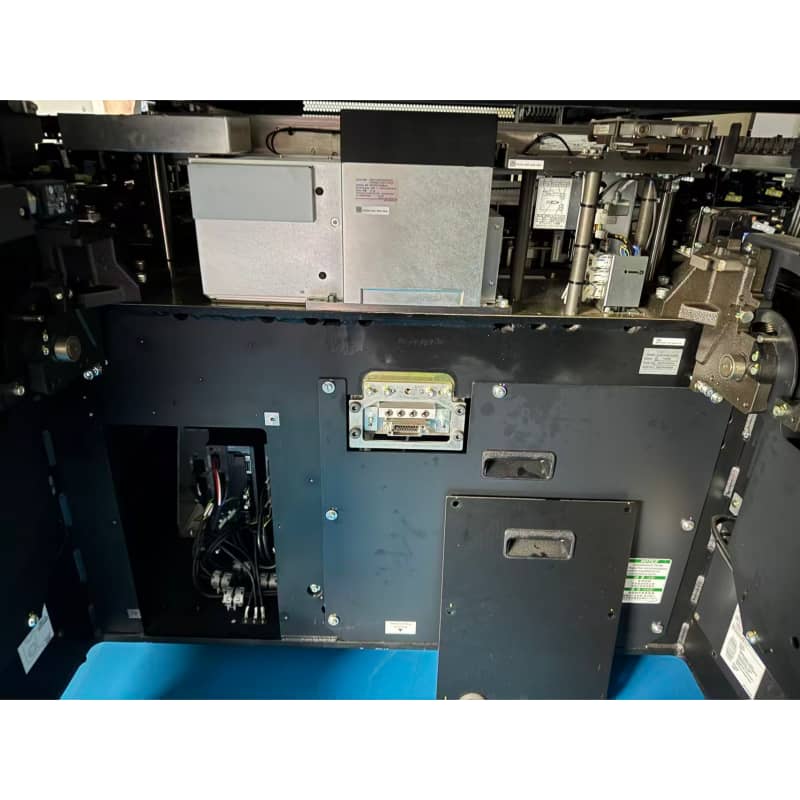

Panasonic Modular Chip Mounter NPM-W2 NM-EJM7D

Feature

1. Dual Independent Functionality (The Main Feature)

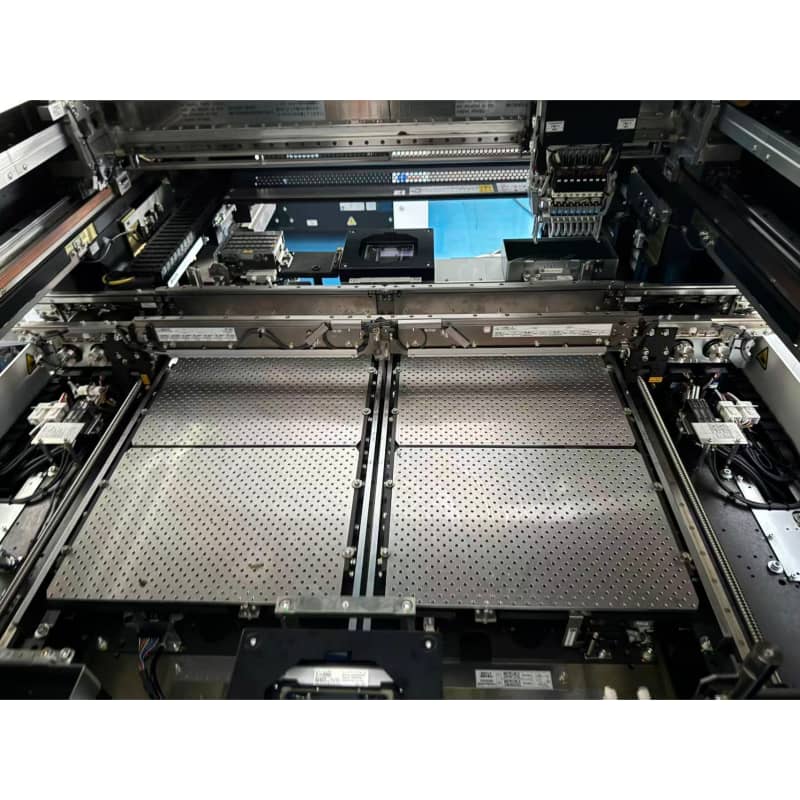

Two Lines in One: The NPM-W2 is essentially two placement machines (NPM-W) combined into a single frame. It has two sets of twin gantries (four independent heads total), each pair operating on its own rail.

Simultaneous, Independent Production: You can run two different board designs, with two different programs, at the same time. This is ideal for High-Mix, Low-Volume (HMLV) production, as setup for one product can occur while the other is running.

No Interdependence: If one “side” (Line A) stops for a feeder change, board issue, or maintenance, the other “side” (Line B) can continue running at full speed without any impact.

2. Other Key Features Enabled by This Design:

Exceptional Flexibility & Uptime: Maximizes production efficiency, especially for complex product mixes, by virtually eliminating setup-related downtime.

High-Speed, Multi-Function Capability: Each side can handle a wide range of components, from 01005 (0.4mm) mini chips up to large 150 x 175mm fine-pitch connectors or odd-form components. It can also be equipped with a 3D inspection unit.

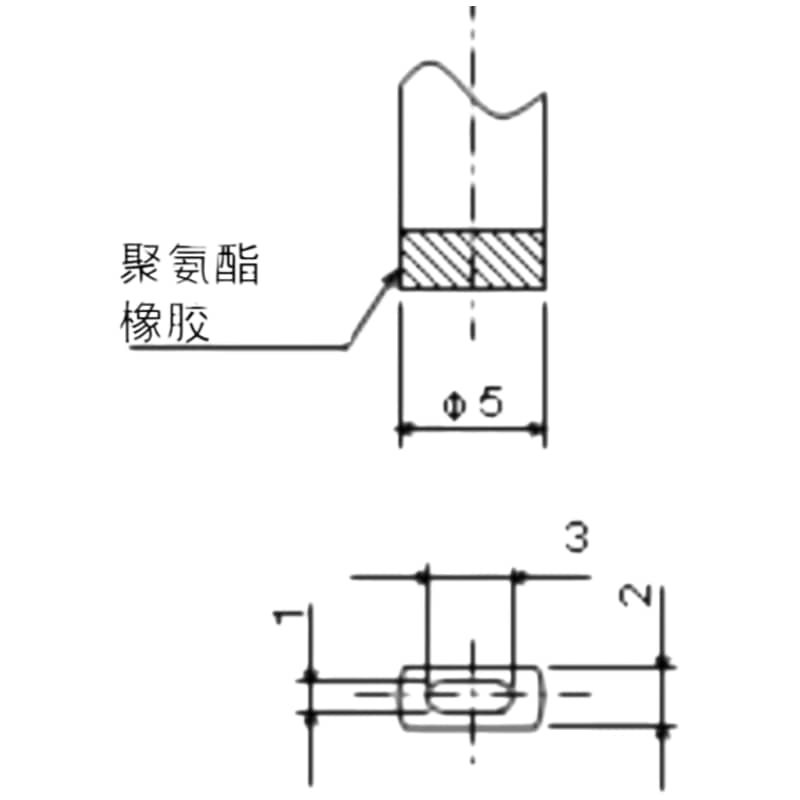

Advanced “W” Nozzle Technology: Uses a dual-head design where two nozzles work in tandem on one spindle for very fast pick-and-place cycles. The proprietary nozzle changer allows automatic nozzle selection from a large on-the-fly magazine.

Material Commonality: Feeders and nozzles are shared with the broader Panasonic NPM platform, simplifying logistics and programming.

Special Skill

The special skill that distinguishes the Panasonic NPM-W2 from other Panasonic SMT machines is its Dual Independent Production Line Capability—the ability to operate as two completely separate placement lines within a single machine frame, with independent gantries, programs, and production schedules. This is a unique architectural feature not found in other NPM series models like NPM-D3 (dedicated high-volume), NPM-TT (twin-tray), or earlier CM series machines.

While other Panasonic machines excel in specific areas (e.g., NPM-D3 for pure speed, NPM-TT for continuous feeding), the NPM-W2’s dual-line independence enables simultaneous production of two different PCB designs without cross-interference—a capability that makes it uniquely suited for high-mix, low-volume manufacturing where changeover flexibility is critical. This “two machines in one” architecture, combined with its wide component range (01005 to 150mm connectors), represents its defining competitive advantage within the Panasonic portfolio.

Core Performance Parameters

Additional Key Features

Dual-Lane Modes:

Independent Mode: Two different PCBs with different programs can run simultaneously.

Alternate Mode: Optimizes throughput for a single PCB type.

Mixed Mode: Flexible combination for complex production.

Recognition System:

Multi-recognition camera system (2D + 3D).

Performs thickness, coplanarity, and presence checks.

Optional Functions:

Dispensing Unit: ±75μm accuracy, 0.16 sec/dot.

3D SPI/AOI (In-line or off-line).

Auto Board Support Pins.

| Parameter Category | Specification |

| Placement Speed | Maximum: 77,000 CPH (Chips Per Hour, theoretical) Typical (IPC9850): ~59,200 CPH (for 1608 components) |

| Placement Accuracy | Standard: ±30μm (Cpk ≥ 1.0) High-Precision Mode: ±25μm |

| Board Size | Single-Lane Mode: 50 x 50mm ~ 750 x 550mm (L x W) Dual Independent-Lane Mode: 50 x 50mm ~ 750 x 260mm per lane |

| Component Range | Minimum: 03015 (0.3 x 0.15mm) microchips Maximum: 150 x 25 x 30mm (L x W x H) large connectors / odd-form parts |

| Head Configuration | Independent for each lane; options include 16-nozzle, 12-nozzle, or 8-nozzle heads. |

| Feeder Capacity | Maximum: 120 stations (8mm tape pitch, using Twin Feeder Configuration) Tape Widths Supported: 4, 8, 12, 16, 24, 32, 44, 56mm |

| Power Requirements | 3-Phase AC, 200/220/380/400/420/480V, 2.8kVA |

| Air Requirements | 0.5 MPa, 200 L/min (A.N.R.) |

| Machine Dimensions (W x D x H) | Approx. 1280 x 2332 x 1444 mm (excluding options) |

| Machine Weight | 18.3 |

| Emissions (Indicated as per international standards) | Approx. 2470 kg (main unit, varies with configuration) |

Our Services

We go beyond delivering powerful machinery to provide a complete partnership built on expertise and unwavering support. Our service ecosystem is designed to ensure maximum uptime, productivity, and return on your investment.

1.Pre-Sales Technical Support

1.1 Technical consultation & line layout planning 1.2 Demo machine testing with customer materials 1.3 Pre-sales training for technical team

2. Delivery & Commissioning

2.1 Professional installation & calibration 2.2 Parameter optimization for specific PCBs 2.3 Trial production validation 2.4 Operator training (SOP, maintenance, troubleshooting) 2.5 Acceptance test with performance verification

3. After-Sales Support

3.1 1-year standard warranty (extendable) 3.2 7×24 hotline, 4-hour emergency response 3.3Scheduled preventive maintenance (quarterly/half-yearly) 3.4 Genuine spare parts supply 3.5 Remote diagnosis & software updates

4. Value-Added Services (Optional)

4.1 Performance upgrades (software/hardware) 4.2 Production efficiency optimization analysis 4.3 Advanced technical training programs 4.4 Extended warranty (2-3 years) 4.5 Equipment relocation service

Our Promise

We are dedicated to being a true partner in your success, providing the tools, knowledge, and continuous support necessary to keep your projects moving forward efficiently and profitably.