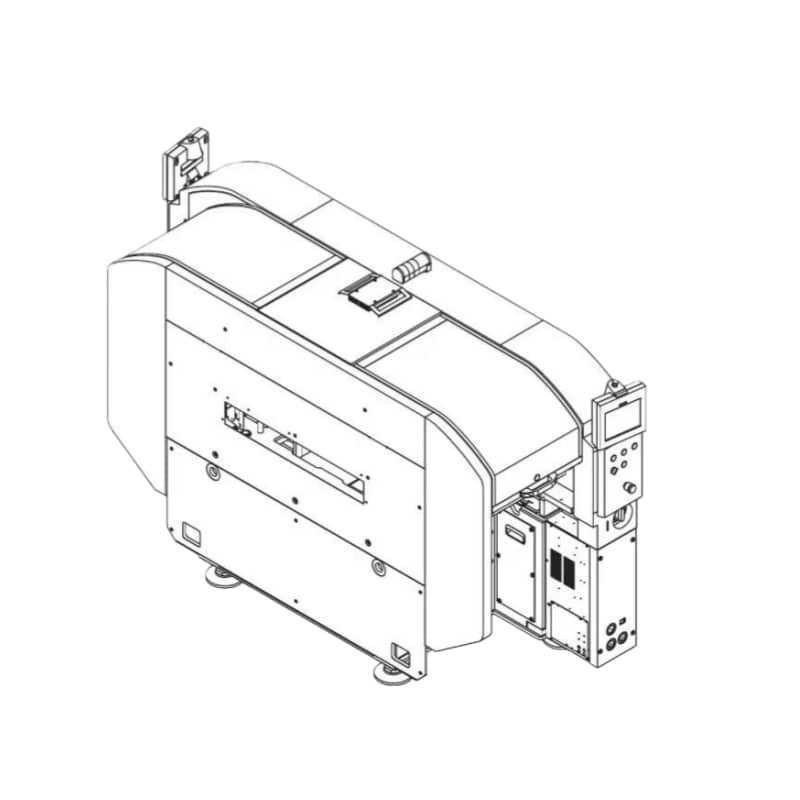

Panasonic Modular Chip Mounter NPM-D3 NM-EJM6D

Feature

1. High-Speed Performance

Placement Speed: Up to 92,000 CPH (components per hour) in optimal configurations

Dual-Lane Operation: Supports simultaneous production on two lanes, doubling throughput

Zero Board Exchange Time: In dual-lane mode, board exchange occurs without stopping production

2. Precision Placement Capability

Placement Accuracy: ±30μm to ±40μm (depending on component type and mode)

Advanced Vision System: Dual laser recognition and high-resolution cameras for component verification

Component Range: Handles components from 01005/0201 metric chips to large connectors (up to L6×W6×T3 mm)

More Features

1. Modular and Flexible Design

Dual-Head Configuration: Supports multiple placement head types (12-nozzle, 8-nozzle, 2-nozzle heads)

Feeder Compatibility: Works with various feeder types including tape, tray, and stick feeders

Scalable Architecture: Modular design allows for easy expansion and integration into production lines

2. Advanced Automation Features

Intelligent Feeder Management: Automatic feeder recognition and setup

Real-Time Calibration: On-the-fly adjustment for optimal placement accuracy

User-Friendly Software: Intuitive interface for programming and production monitoring

3. Production Efficiency

High-Mix Capability: Handles multiple product types on the same line with quick changeovers

Low Maintenance Design: Reduced downtime with easy access to consumable parts

Compact Footprint: Space-efficient design despite high performance

4. Application Versatility

Suitable for various industries including consumer electronics, automotive electronics, telecommunications, and medical devices, supporting components from microchips to large odd-form devices.

The NPM-D3 is particularly valued for its combination of speed, precision, and flexibility in high-volume SMT manufacturing environments.

Core Performance Parameters

Additional Key Features

Dual-Lane Modes:

Independent Mode: Two different PCBs with different programs can run simultaneously.

Alternate Mode: Optimizes throughput for a single PCB type.

Mixed Mode: Flexible combination for complex production.

Recognition System:

Multi-recognition camera system (2D + 3D).

Performs thickness, coplanarity, and presence checks.

Optional Functions:

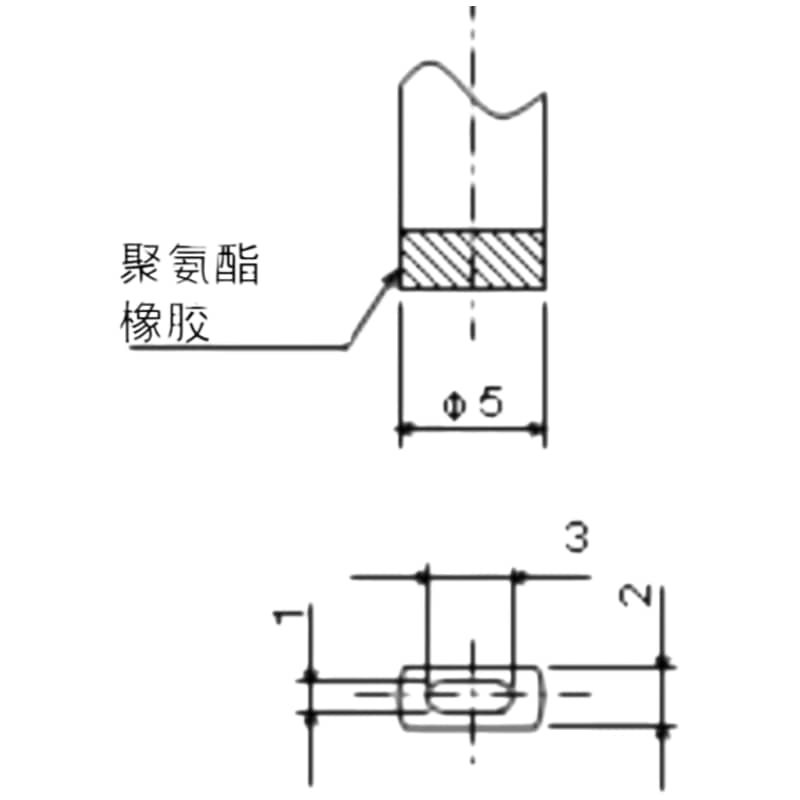

Dispensing Unit: ±75μm accuracy, 0.16 sec/dot.

3D SPI/AOI (In-line or off-line).

Auto Board Support Pins.

| Parameter Category | Specification |

| Placement Speed | Up to 92,000 CPH (components per hour) |

| Placement Accuracy | ±30μm to ±40μm |

| Component Range | 01005/0201 chips to L6×W6×T3mm large components |

| Dual-Lane Operation | Simultaneous production on two lanes |

| Modular Design | Scalable with multiple head configurations |

| Vision System | Dual laser + high-resolution cameras |

| Feeder Compatibility | Tape, tray, and stick feeders |

| Zero Board Exchange | Continuous production in dual-lane mode |

Our Services

We go beyond delivering powerful machinery to provide a complete partnership built on expertise and unwavering support. Our service ecosystem is designed to ensure maximum uptime, productivity, and return on your investment.

1.Pre-Sales Technical Support

1.1 Technical consultation & line layout planning 1.2 Demo machine testing with customer materials 1.3 Pre-sales training for technical team

2. Delivery & Commissioning

2.1 Professional installation & calibration 2.2 Parameter optimization for specific PCBs 2.3 Trial production validation 2.4 Operator training (SOP, maintenance, troubleshooting) 2.5 Acceptance test with performance verification

3. After-Sales Support

3.1 1-year standard warranty (extendable) 3.2 7×24 hotline, 4-hour emergency response 3.3Scheduled preventive maintenance (quarterly/half-yearly) 3.4 Genuine spare parts supply 3.5 Remote diagnosis & software updates

4. Value-Added Services (Optional)

4.1 Performance upgrades (software/hardware) 4.2 Production efficiency optimization analysis 4.3 Advanced technical training programs 4.4 Extended warranty (2-3 years) 4.5 Equipment relocation service

Our Promise

We are dedicated to being a true partner in your success, providing the tools, knowledge, and continuous support necessary to keep your projects moving forward efficiently and profitably.